inlet 1/2", 3/4" or 1" - outlet 3/4" or 1" - seat orifice Ø6 mm or Ø8 mm - set pressure from 0,5 bar g. to 460 bar g.

Description

Bronze safety valve without lever, with screwed inlet and threaded outlet in its standard version. The tightness is ensured through a very neat lapping of the seat and plug. A wide range of springs enables an accurate pressure setting for this PED 97/23/CE Category IV Group 2 certified saftey valve.

Applications

Designed for use on all air components gases in its standard version, this safety valve offers a wide range of options which allows the handling of a large variety of fluids. This safety valves is extensively is extensively used in every kind of industrial projects: liquid storage tanks, air separation units, petrochemical plants, dangerous products transportation, ... Some options enable oxygen service.

General features

- Bronze construction

- Safety valve's behaviour adjustable thanks to two blow-down rings

- The sturdy design, the high-quality of the selected materials and the high-performance components of this safety valve provide to it multi-purpose characteristics

- Internal trim made of nickel alloy (#Monel™)

- Shoulder seat made of nickel alloy (Monel 400™)

- Inlet and outlet as per ISO R228 or ASME/ANSI B2-1

Alternatives

- Flanged inlet and outlet

- Butt welding fittings at inlet and/or outlet

- Cap with lever

- Gas-tight construction

- ... (see codification)

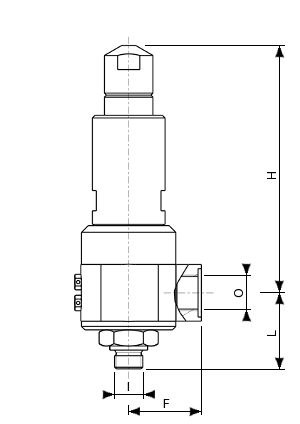

| Dimensions in mm | Weight (W) in kg | ||||||

| Inlet(G or NPT) | L | Outlet(G or NPT) | F | do | H | W | |

| 35 < Ps < 320 | 321 < Ps < 460 | ||||||

| 1/2" | 56,5 | 3/4" | 54 | 8 | 6 | 184 | 3,5 |

| 3/4" | 58,5 | 3/4" | 54 | 8 | 6 | 184 | 3,5 |

| 1" | 60,5 | 3/4" | 54 | 8 | 6 | 184 | 3,5 |

| 1/2" | 56,5 | 1" | 54 | 8 | 6 | 184 | 3,5 |

| 3/4" | 58,5 | 1" | 54 | 8 | 6 | 184 | 3,5 |

| 1" | 60,5 | 1" | 54 | 8 | 6 | 184 | 3,5 |

| Ps: Set pressure (bar g.) | |||||||

| For other gases (MW): multiply the air rated flow by sqrt[29/MW] For other temperatures (T): multiply the air rated flow by sqrt[273/(T+273)] - T in °C |

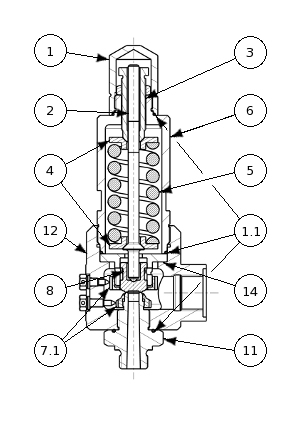

| Standard materials | |||||

| Rep | Designation | Standard materials | |||

| 1 | Cap | EN 1982 | |||

| CuSn7Pb6Zn4 CC493K | |||||

| B505.836 | |||||

| 1.1 | Gasket | PTFE | |||

| 2 | Stem | Monel K500™ | |||

| UNS N05500 | |||||

| NiCu29Al3Mn | |||||

| 3 | Adjusting screw | EN 12164 | |||

| CuZn36Ni2 2.0540 | |||||

| - | |||||

| 4 | Spring plate | EN 10088-3 | |||

| X8CrNiS18-9 1.4305 | |||||

| AISI 303 | |||||

| 5 | Spring | EN 10088-1 | |||

| X10CrNi18-8 1.4310 | |||||

| AISI 302 | |||||

| 6 | Lantern | EN 1982 | |||

| CuSn7Pb6Zn4 CC493K | |||||

| B505.836 | |||||

| 7.1 | Blow-down ring | EN 12164 | |||

| CuZn39Pb3 CW614N | |||||

| B124-C37700 | |||||

| 8 | Plug | Monel 400™ | |||

| UNS N04400 | |||||

| NiCu30FeMn + Colmonoy 5™ | |||||

| 11 | Shoulder seat | Monel 400™ | |||

| UNS N04400 | |||||

| NiCu30FeMn + Colmonoy 5™ | |||||

| 12 | Body | EN 1982 | |||

| CuSn7Pb6Zn4 CC493K | |||||

| B505.836 | |||||

| 14 | Guide | EN 12164 | |||

| CuZn39Pb3 CW614N | |||||

| B124-C37700 | |||||

| 7 | 7 | 5 | 1 | 0 | 0 | - | X | X | X | - | 00 | 00 | 00 | - | DN | .. | PN | .. |

|---|

| 7 | 7 | 5 | 1 | 0 | 0 | - | X | X | X | - | 00 | 00 | 00 | - | DN | .. | PN | .. |

|---|

| Value | Inlet connection |

|---|---|

| 2 | Screwed end |

| 3 | Flanges |

| 4 | Butt welding fitting |

| 7 | 7 | 5 | 1 | 0 | 0 | - | X | X | X | - | 00 | 00 | 00 | - | DN | .. | PN | .. |

|---|

| Value | Pressure rating |

|---|---|

| 8 | PN320 |

| 9 | PN420 |

| 7 | 7 | 5 | 1 | 0 | 0 | - | X | X | X | - | 00 | 00 | 00 | - | DN | .. | PN | .. |

|---|

| Value | Option |

|---|---|

| E | ATEX CE Ex II 2G/D |

| 7 | 7 | 5 | 1 | 0 | 0 | - | X | X | X | - | 00 | 00 | 00 | - | DN | .. | PN | .. |

|---|

| Value | Option |

|---|---|

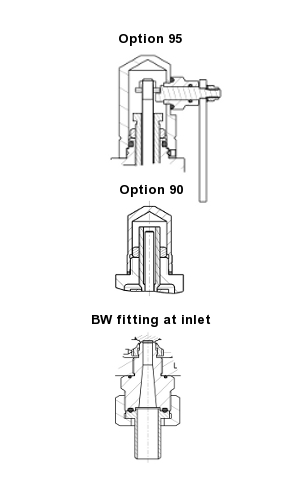

| 80 | Spacer |

| 85 | Butt welding fitting at outlet |

| 86 | Collected outlet |

| 90 | Regular bonnet |

| 92 | Gas tight body and bonnet |

| 95 | Gas tight cap with lever |